Why should I consider using high efficiency PERC cell solar panels for some projects? June 23 2016

For the past year PERC solar cell technology has been inscreasing it's popularity in the high efficiency sector of the Solar PV Industry.

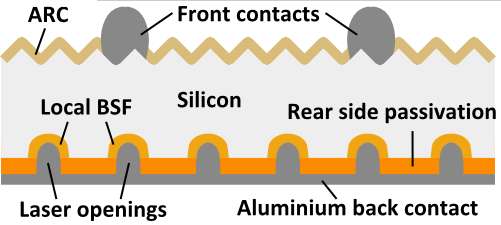

PERC stands for Passivated Emitter Rear Contact, and refers to the dielectric layer on the back of a PERC solar cell.

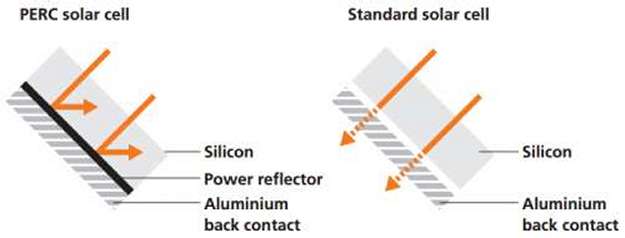

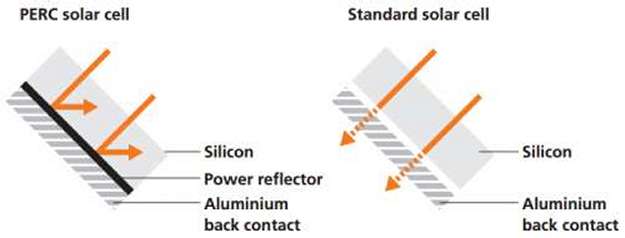

This layer on the back of the PERC solar cells help to reflect light, that passed through the cell, back into the cell so it can generate more electrons. This is also known as backside passivation with internal rear reflector. This is a feature that standard normal MONO and POLY cells don't have.

PERC: both efficiency increase and system cost reduction?

When it comes to R&D, there are two obvious focus points in our industry: cost reduction and efficiency increase.

With efficiencies passing the 20%+ mark, PERC solar cell technology surely has an advantage compared to conventional P-type Silicon Solar Cells which only produce around 18-19% efficiency.

The efficiency gains of PERC technology translates into a 5-50W power increase for a 60 cell panel.

Besides higher efficiency, PERC solar cell technology will potentially have a cost advantage as well (when labour and mounting hardware is factored in). However, this requires that sufficient PERC manufacturing capacity has been installed and production has been ramped up (which is only just starting to happen).

Who are the main Solar manufacturers with PERC solar cell technology?

Some of the main companies around the world producing PERC Cells & PERC Panels are listed below.

JA Solar - PERCIUM solar cells

The expected production capacity of JA Solar’s PERCIUM solar cells is 350MW in 2015, which is only a small part of its total expected 3.6-4.0 GW sales capacity (PV-Tech).

The company has reached average conversions efficiency of 20.4%. JA Solar started marketing its PERCIUM 60 cell solar panel in 2015 mostly in the Japanese, British, Israeli, Chinese and German markets.

Winaico & Solarworld - PERC Cell Panels

Winaico & Solarworld were 2 other leading solar panel manufacturers around the world to start producing PERC cell panels (only for their highest efficiency panel offerings).Suntech - HYPRO Solar Cells

Good to see that Shunfeng, the owner of the Suntech brand, is also investing in upgraded production lines at Suntech and has been implementing PERC solar cell technology.

The first Suntech Hypro module production line came online in July 2015 and Suntech has started shipping out high efficiency modules for its first projects and it's own panels as well as to other high end panel companies who wish to built high efficiency PERC Cell panels also.

Suntech’s 60cell, 300W modules reach a max. of 20.8% conversion efficiency.

The Suntech PERC Cells are now all running on 4BB (4 Bus Bar) style cells to further increase efficiency and lower losses more than 3BB (3 Bus Bar) cell panels were able to achieve.

Hitek Solar NZ - PERC MONO Solar Panels

We design our own highest quality panels using only highest efficiency PERC MONO cells. In 2020 we released our latest 330w Rear Contact PERC MONO Panels (replacing our previous 315w 5bb PERC MONO Panels). These are some of the best quality most advanced PERC MONO panels available in the world today and as such they can collect more sunlight in ALL weather condtions especially during the morning / afternoons / evenings and also during cloudy / overcast weather conditions. We are using 22.5% cell efficiency in our 330w Rear Contact PERC MONO panels (1640x995 panel size) and we've also just released our latest 72 half cut cell 205w 5BB PERC MONO Panels (22.3% cell efficiency) at 1518x684mm panel size. These 2 new panel offerings are 2 of the most advanced PERC MONO panels (in their physical size) available in NZ today (May 2020) and per rated watt we've seen during our own testing MORE power in cloudy / overcast NZ days than other standard panels and more budget / entry level lower efficiency PERC panels.

Our PERC Mono Panels are available in watts 330w for 60 Cell panel size (1640 x 995mm size).

Our PERC Mono Panels are available in watts 205w for 72 half cut cell panel (almost the same size as a standard 36 cell panel) but much higher real world & cloudy day output power (1518 x 684mm size).

Typically we can give MORE output on your roof area of your home, bus, caravan, tiny home, campervan, batch or cottage than 99% of other solar companies in NZ thanks to our own unique high efficiency panels (designed by Hitek Solar NZ directly).

We only use the highest quality Tigo Energy Upgradable Junction Box on our panels and this allows any of the Tigo TS4 Shade Optimization Cartridges to simply be clipped into our panels (if there's any panels that have any shading issues affecting others on the string etc). Our panels use only the highest quality Anti-Reflective Self-Cleaning Glass Technology (with slippery Nano Coating factory applied) and are TUV tested for Fire Rating, Acid / Salt / Corrosion Mist Tested and PID (Potential Induced Degredation) Free tested also.

Our PERC Panels are able to offer higher output wattages available to our customers right now than those currently offered by Trina Solar and JA Solar Today (at the current time) due to our strict selection process choosing only the best and highest efficiency cells to be used in our panels. We are lucky enough to have one of the largest high quality panel manufacturers in the world physically building our panels for us to our exact highest quality specifications and have access to some of the best highest efficiency solar cells in the world.

When you compare 3BB (bus bar) cells panels vs 4BB (bus bar) cell panels, our panels with 4 Bus Bars have 25% better connectivity with the other cells in the panel which translates into a more reliable, long lasting and higher output panel over the 25+ year life of the panel. It's like comparing a 3 lane motor way with a 4 lane motor way, you suddenly have an entire extra lane to help make that traffic flow more smoothly with less congestion and at a better more consistent flow, hence why we've moved all of our 265w and higher panels over to 4BB as standard for our panels (while still keeping the cost the same to our customers as our previous 3BB panels that we had been supplying for the last 5 years).

2020 Update our latest 330w Rear Contact panels are MORE efficient than even a 12 or 16 bus bar panel, and our latest 205w half cut cell 5BB panel would be equal to a 12BB full cell panel in terms of panel efficiency losses.

Trina Solar – Honey M Plus

During 2015, Trina Solar launched both a poly and mony PERC solar module, called Honey Plus. The mono module is called Honey M Plus.

The Poly Honey Plus reached an efficiency of 18.7%, 60cell reaches 275W, while the Honey M Plus has a conversion afficiency of 20.5%, which makes a 60cell module 290W.

How does PERC cell technology improve solar panel performance?

As mentioned already, PERC solar cells are designed with an additional layer at the bottom of the solar cell. This extra layer is called the dielectric passivation layer (also known as rear side passivation).

There are three main reasons why the dielectric / rear side passivation layer contributes to the increase of efficiency:

-

The extra rear dielectric passivation layer reduces electron recombination:

Electron recombination is the tendency of electrons to recombine and basically block the electrons from freely flowing through the solar cell, which means it can’t reach its potential efficiency.Electrons generated near the back of the solar cell are now free to move up to the emitter and contribute to more electrical current.

-

The extra dielectric passivation layer increases the solar cell’s ability to capture light:

The dielectric layer reflects the light that passes through the solar cell without generating any electrons. By reflecting this light, the photons are given more opportunity to generate electrical current.

-

The extra dielectric passivation layer reflects wavelengths above 1180 nm out of the solar cell, that would normally create heat:

Silicon wafers stop absorbing wavelengths above 1180 nm. In normal solar cells, such wavelengths are easily absorbed by the backside metallization and turned into heat (the more heat absorbed by the cells, the lower the power output and the less heat absorbed by the cells the higher the power output).

Comparison PERC solar cell and standard solar cell.

As you know, heat reduces the solar cell’s conversion efficiency. The dielectric passivation layer reflects wavelengths above 1180 nm out of the solar cell, and helps the solar cell to work more efficiently by maintaining cooler temperatures.

Review: how is electricity generated from a solar cell?

A conventional crystalline silicon (c-Si) solar cell consists of two layers with different electrical properties. The two layers are called the base and the emitter. The point where the base and emitter meet is called the interface.

An electrical field is generated where the two layers touch - this point is called the interface. The interface pulls negatively charged electrons into the emitter once reaching the interface.

When light enters the solar cell, the electrons are released from the silicon atoms.

When electrons are released, they can travel freely through the silicon wafer. However the electrons will only contribute to the electrical current if they reach the interface, between the emitter and the base..

Once electrons reach the interface, they’re pulled into the emitter and will create a voltage difference over the solar cell.

Different types of wavelengths

Shorter wavelengths (blue light) mainly generate electrons near the front of the solar cell, while the longer wavelengths (red light), will generate electrons at the back of the cell. Some of the longer wavelengths will pass through the wafer without generating any current.

This is where the dielectric layer on the back of the solar cell makes the difference.

How PERC cell technology catches different wavelengths and why is this important?

The sun emits light in different wavelengths and when the light reaches the silicon cell structure, it generates electrons at various levels of the solar cell structure.

PERC technology increases the cell’s ability to catch longer wavelengths. The longer wavelengths are especially present during mornings and evenings (sun under an angle) or during cloudy days.

Blue light, with shorter wavelengths, is being absorbed by the atmosphere during these times, as it has to travel a longer path to reach the Earth’s surface. Red light is less easily absorbed by the Earth’s atmosphere.

So the main reason why PERC technology shows better energy yields is the reflective dielectric layer on the back of the solar cells which helps to absorb more red light, even during the morning / afternoons / evenings and also during cloudy / overcast weather conditions.

PERC’s impact on real world solar installations

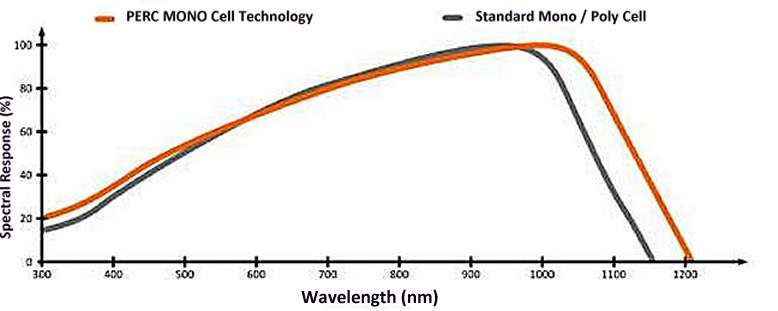

Figure 3: Differences in spectral response between a PERC solar cell and a standard solar cell.

The total energy in sunlight is the sum of energy across a wide range of wavelengths. Therefore a good solar cell technology needs to have excellent spectral response, across all wavelengths, matching the sunlight. When the sun shines on a standard solar cell, the shorter wavelengths below 500 nm (blue light) get absorbed by the solar cell, but the longer wavelengths above 620 nm (red light and infrared) may pass through the solar cell without being converted into useful energy. The extra reflector layer in the PERC solar cell is effective at reflecting infrared wavelengths longer than 1,000 nm for a second absorption phase, resulting in better response than standard cell technology across the whole spectrum, shown in Figure 3.

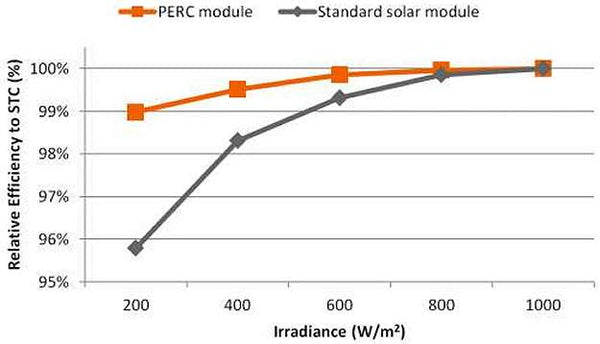

Figure 4: Differences in relative efficiency at different irradiance levels between a PERC module and a standard solar module.

During low light (dawn and dusk) and weak light (cloudy) conditions, the shorter wavelength blue light gets absorbed by the atmosphere, allowing higher proportion of long wavelength light to reach Earth. In such situations, PERC solar cells’ improved spectral response at long wavelengths allows the cells to perform better than standard cells, and maintain close to top efficiency at low light conditions, as illustrated by Figure 4. Hitek Solar PERC modules are able to maintain close of 99% of its STC efficiency at 200 W/m2 irradiance level, while a standard solar module’s relative efficiency drops to less than 96% at the same condition.

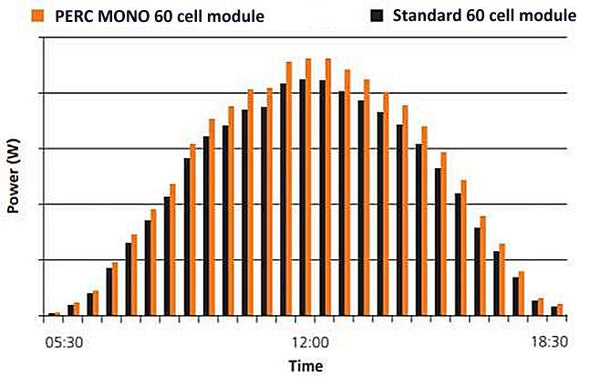

Figure 5: Differences in energy output across a whole day between a PERC module and a standard Mono / Poly Silicon solar module.

As a result, the energy output of a Hitek Solar PERC module is higher than a standard module across a whole day, shown in Figure 5. A PERC Solar panel installation is known to begin producing electricity earlier in the morning and stops later in the evening than an installation of conventional solar modules. This is well worth considering if owners of off-grid systems are serious about the ability to maximize their daily power production to run their home and re-charge their batteries again, however it does currently come at a small cost premium compared with standard Poly and Mono cell panels.

When I'm building an off-grid system should I just be looking at the "SUMMER PEAK PANEL OUTPUT WATTAGE" as most people & other solar power companies do?

No, sadly many people get wrongly miss-lead thinking that standard 250-270w panels from any vendor will do for their off-grid projects, not realising that they are only considering "PEAK PANEL POWER OUTPUT" which only applies in the middle of the day on the BEST Summer days and this does NOT help them at all with the most critical time of the year which is for their Winter / Autumn and Spring power production. If you care about the GREATEST Winter Output then you cannot simply base your system size on a panels "PEAK Summer Production Wattage" but should instead be looking at using PERC Panels to give you the best production even on those days with more gloomy weather (which is actually usually when you need the power production the most). On-Grid / On-Grid Hybrid system owners may not care as much about this as they have the grid there to fall back on during periods of bad weather, where as off-grid customers would in turn have to start up their generator if their batteries are not being charged enough during Winter Periods (which means further cost is incurred because of running the generator).

Please be aware that at the current time there are only around 10-12 of the world's high end solar cell / panel production companies that have access to these latest PERC cells and are producing PERC cell panels, so if your solar panel vendor tries to tell you that you are getting PERC panels (when you ask them) please make sure that they're able to back this up by telling you the exact cells that will be used in your panels. Typically at the current time most PERC cell panels will be between 280w - 310w for 60 cell panels and between 330-350w for 72 cell panels. If you are told that your 3 Bus Bar 60 cell 250w, 260w, 265w or 270w panels are using PERC cells then most likely that is simply NOT true as all PERC cell panels are HIGH EFFICIENCY panels (with 5 Bus Bars or more). If you want the ULTIMATE PERC MONO Panels then specify those with a cell efficiency of 22.3% or higher (available starting from 2020).

If you had a small setup such as a Tiny Home, or RV / Campervan / Caravan etc where you could only fit a couple of panels, then potentially it can make sense to want to use PERC cell panels for these projects as often you are needing maximum power output from very small and limited roof space areas (and some home roof tops also fit into this same category when they're limited by not much good usable un-shaded space).

It should be noted that within the next 4 years ALL major top brand panel manufacturers will be switching their production over to PERC cell panels as standard, however at the current time they still cost a small premium more than standard cell panels, but rest assured that sometime in the future this technology will become the mainstream technology used in all high quality solar panels (just as smart phones have became the standard phones in the world today).

If you have any questions about PERC Solar Cell / Panel technology or even our Shade Optimization Solution, please talk to us so we can best assist and advise you further thanks.